ChatGPT said:

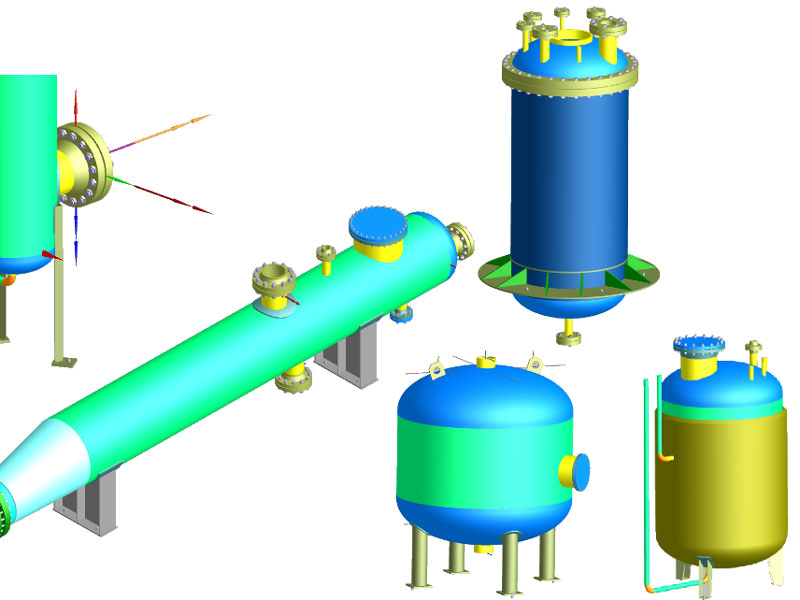

Process Equipment Design Course in Mumbai provides students with detailed knowledge and practical skills essential for designing and sizing key industrial equipment. The course focuses on components commonly used in sectors like oil & gas, chemical, and petrochemical industries. Students will explore the design principles behind critical systems such as pumps, heat exchangers, and reactors while also learning about safety protocols, industry standards, and energy-efficient practices.

In addition to theoretical understanding, the course emphasizes hands-on learning through real-world projects and case studies. Learners will become proficient in using advanced design software, equipping them for crucial roles in process engineering. The Process Equipment Design Course in Mumbai ensures that students are well-prepared to meet industry demands with confidence and competence.

Field Scope & Importance

- Learn the fundamentals of designing pumps, compressors, heat exchangers, and reactors.

- Understand and apply global design codes like ASME, API, and TEMA

- Gain hands-on experience with tools like Aspen HYSYS and AutoCAD for process design.

- Work on case studies and live projects to apply theory in practical scenarios.

- Emphasize safety, reliability, and operational efficiency in equipment planning.

- Prepare for roles in EPC companies, design consultancies, and process industries worldwide.

Eligibility

- B. Tech / B.E in Mechanical/ Chemical

- Diploma in Mechanical/ Chemical

- M.Tech / M.E in Mechanical/Chemical

Working Steps for Process Equipment Design

Conceptual Design

Identify the process requirements and determine the type of equipment needed. Ensure the design aligns with operational and safety standards.

Detailed Design

Create detailed drawings and specifications for equipment, including materials, dimensions, and performance criteria. Validate design against industry codes and regulations.

Prototype & Test

Build prototypes or simulate the equipment’s operation under real-world conditions. Perform tests to ensure reliability and functionality.

Fabricate & Install

Oversee the manufacturing process, ensuring quality control and adherence to specifications. Supervise installation and integration of equipment into the plant system.

Curriculum

- Basic considerations in Process Equipment Design

- Material Of Construction

- Design Considerations

- Design Of Machine Elements

- Pressure Vessels

- Storage Vessels

- Reaction Vessels

- Heat Exchangers

- Evaporators And Crystallizers

- Distillation And Absorption Towers/Columns

- Auxiliary Process Vessels

- Supports For Vessels

- Mixers

- Filters

- Drayers

- Process Hazards And Safety Measures In Equipment Design

- Process Flow Diagrams

Core Functions of Process Design Equipment Course

Complete Equipment Design

Learn to design and size key process equipment like pumps, heat exchangers, reactors.

Industry Standards

Understand global standards and codes like ASME, API, and ASHRAE used in equipment design.

Hands-on Training

Gain practical experience in the design and analysis of real-world equipment through case studies.

Software Proficiency

Master industry-standard software tools like Aspen Plus and AutoCAD for equipment design.

Process Integration

Learn how equipment fits into the broader process flow and its impact on overall system efficiency.

Safety and Efficiency

Emphasize safe and efficient design practices to optimize process operations and minimize risks.

A Process Equipment Design Course in Mumbai at Trinkets Institute of Technology (TIT) equips you with the skills to create efficient, safe, and innovative process equipment like reactors, heat exchangers, and columns. Mumbai, India’s hub for oil, gas, and chemical industries, is the perfect place to pursue a Process Equipment Design Course in Mumbai. This article highlights why TIT’s course is a career-defining choice, what you’ll master, and how it prepares you for success in high-demand sectors.

Why Choose a Process Equipment Design Course in Mumbai?

Powering Industrial Operations

Process equipment, such as distillation columns and pressure vessels, is critical for the smooth operation of refineries, chemical plants, and pharmaceutical facilities. Mumbai’s industrial giants, like Reliance Industries, BPCL, and Aarti Industries, rely on skilled engineers to design robust equipment that meets stringent standards. TIT’s Process Equipment Design Course in Mumbai trains you to develop equipment that optimizes performance and ensures safety, positioning you as a top candidate for roles in EPC firms and consultancies.

Mumbai’s Industrial Hub

Mumbai’s proximity to refineries, petrochemical complexes, and engineering projects makes it ideal for a Process Equipment Design Course in Mumbai. TIT’s Mulund campus connects you to this thriving ecosystem, offering hands-on exposure and access to high-demand job markets. From green energy projects to chemical plant expansions, Mumbai provides the perfect platform to launch your career.

What You’ll Learn in TIT’s Process Equipment Design Course

Comprehensive Curriculum

TIT’s Process Equipment Design Course in Mumbai delivers a focused curriculum over 1-3 months, with flexible weekday, weekend, or online batches. Designed for both beginners and professionals, the course covers:

Equipment Design Principles: Learn to design heat exchangers, reactors, and towers using ASME and TEMA standards.

Software Tools: Master PV Elite, HTRI, and AutoCAD for equipment design and analysis.

Material Selection: Understand material properties for corrosion resistance and durability.

Safety and Compliance: Ensure designs meet API, IS, and HSE regulations.

Fabrication Drawings: Create detailed drawings and specifications for manufacturing.

Through hands-on projects, like designing a heat exchanger for a refinery, you’ll gain practical expertise. The course aligns with TIT’s SketchUp Course in Mumbai, enabling you to create 3D visualizations of equipment designs for enhanced project presentations.

Industry-Focused Training

With small batches of 7-10 students, TIT ensures personalized instruction from expert instructors. You’ll tackle real-world challenges, such as optimizing a pressure vessel for cost and safety, preparing you to meet industry standards with precision. Exposure to tools like Aspen Plus ensures you’re ready for integrated design workflows.

Why TIT is the Premier Choice

Expert Faculty and Certification

Since 2011, TIT has been ISO 9001:2015 certified, delivering industry-aligned training. Our Process Equipment Design Course in Mumbai is led by professionals with extensive experience in equipment design and plant engineering. You’ll earn globally recognized certificates, valued by employers like TechnipFMC and Thermax, boosting your professional credibility.

Affordable Fees and Proven Placements

TIT offers competitive fees, ensuring accessibility for all. Our placement cell boasts an 80% success rate, with alumni like Shubham Patil (Tata Consulting Engineers, 6 lakhs/year) and Mahesh Gosavi (Tata Consulting Engineers, 7.2 lakhs/year) securing top roles. TIT provides resume-building workshops, mock interviews, and direct connections to industry recruiters.

Career Opportunities After the Course

A Process Equipment Design Course in Mumbai unlocks roles like equipment design engineer, process designer, or plant engineer. Starting salaries range from 4-6 lakhs annually, with experienced professionals earning 10 lakhs or more. Mumbai’s industrial sector, driven by projects like refinery upgrades and sustainable manufacturing, ensures strong demand for equipment design expertise.

Why Choose TIT in Mumbai?

TIT’s Process Equipment Design Course in Mumbai is a career accelerator, combining practical training, expert mentorship, and robust placement support. Located in Mulund, with online options, TIT offers flexibility to suit your lifestyle.

Take the Leap Today

Don’t wait to shape your future. A Process Equipment Design Course in Mumbai at TIT empowers you to design critical equipment that powers global industries. Enroll now to master process equipment design and launch a rewarding career in Mumbai’s dynamic industrial landscape.