PV ELite Course in Mumbai provides you a powerful engineering software used extensively for the design, analysis, and evaluation of pressure vessels and heat exchangers in accordance with international codes like ASME. It simplifies complex mechanical calculations, ensuring safe and code-compliant vessel design for industries such as oil & gas, petrochemicals, and power generation.

Engineers using PV ELite can efficiently model, simulate, and validate critical pressure components with accuracy, thanks to its intuitive interface, built-in code libraries, and robust analysis capabilities. With increasing emphasis on safety and regulatory compliance, skilled PV ELite professionals are highly valued across EPC firms, design consultancies, and fabrication companies.

Field Scope & Importance

- Critical for Pressure Vessel Design

- Ensures Code Compliance

- Widely Used in EPC and Fabrication

- Optimizes Structural Integrity

- Supports Multidisciplinary Integration

- High Demand in Oil & Gas and Petrochemicals

Working Steps for PV ELite

Design Parameters

Set the design parameters such as material specifications, pressure, temperature, and other key inputs to ensure accurate calculations.

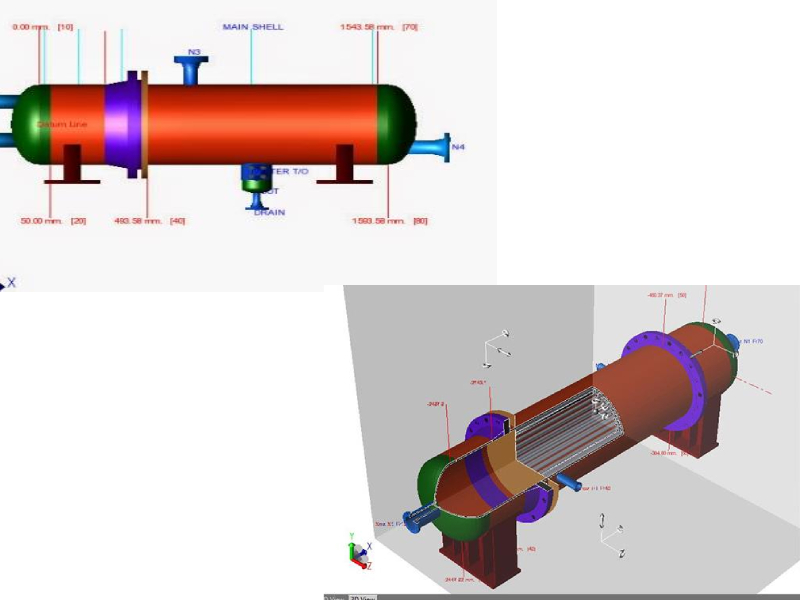

Model the Vessel

Use PV Elite's modeling tools to create a 3D representation of the pressure vessel, specifying the geometry and components.

Perform Analysis

Conduct various analyses, including stress, fatigue, and code compliance checks, to ensure the vessel meets safety and regulatory standards.

Generate Reports

Automatically generate detailed design, stress analysis, and compliance reports, ensuring they meet industry codes and regulations.

Curriculum

- KEY TOPICS COVERED

- Basic Vessel Components & Analysis

- Additional Vessel Components & Analysis

Compliance-Focused Training

ASME Code Mastery

Gain in-depth understanding of ASME Section VIII Div. 1 & 2 for accurate and compliant vessel design. Learn to apply code rules directly within PV Elite to meet industry standards.

Material Selection & Certification

Train on selecting materials that comply with international codes and pressure ratings. Understand material properties, certifications, and temperature limits.

Design Verification & Stress Analysis

Perform detailed verification of vessel components under pressure, wind, and seismic loads. Ensure structural integrity through automated and manual checks.

Documentation & Reporting Standards

Learn to generate code-compliant design reports and documentation for regulatory submission. Ensure traceability, accuracy, and audit-readiness in all deliverables.

Inspection & Testing Readiness

Understand the role of design in inspection planning and non-destructive testing (NDT). Prepare vessels for inspection phases with properly calculated tolerances and allowances.

Global Compliance & Export Formats

Create design files and reports compatible with global clients and fabrication partners. Use export features to align with international regulatory and documentation needs.

Want to master pressure vessel design and stand out in the oil and gas industry? A PV Elite Course in Mumbai at Trinkets Institute of Technology (TIT) is your path to expertise in PV Elite, the industry-standard software for designing and analyzing pressure vessels and heat exchangers. Mumbai, a powerhouse for engineering and industrial projects, is the ideal place to enroll in a PV Elite Course in Mumbai. This article dives into why TIT’s course is a career catalyst, what you’ll learn, and how it sets you up for success, alongside complementary training like the MEP Engineering course.

Why Choose a PV Elite Course in Mumbai?

Industry Demand for PV Elite Expertise

PV Elite is critical for designing pressure vessels and heat exchangers that meet global codes like ASME VIII, EN 13445, and PD 5500. Mumbai’s thriving oil, gas, and petrochemical sectors need engineers who can deliver precise, compliant designs. TIT’s PV Elite Course in Mumbai equips you with hands-on skills to model vessels, analyze stresses, and ensure safety, making you a top pick for firms like Reliance Industries or L&T Hydrocarbon.

Mumbai’s Engineering Hub

Mumbai’s industrial landscape, from refineries to EPC projects, makes it perfect for a PV Elite Course in Mumbai. TIT’s Mulund campus connects you to this ecosystem, offering real-world exposure and job opportunities in a city driving India’s energy sector.

What You’ll Learn in TIT’s PV Elite Course

Comprehensive Curriculum

TIT’s PV Elite Course in Mumbai covers PV Elite from the ground up. You’ll master:

Modeling vertical and horizontal vessels

Designing nozzles, flanges, and saddles

Performing stress analysis per ASME VIII-1 and EN 13445

Generating detailed reports and 2D drawings

Conducting Fitness for Service (FFS) analysis per API 579

Spanning 1-2 months, the course offers flexible weekday, weekend, or online batches. You’ll tackle live projects, like designing a heat exchanger, to gain practical skills. Integration with tools like CADWorx enhances your ability to collaborate on broader MEP projects, such as those covered in TIT’s MEP Engineering course.

Hands-On and Industry-Relevant

With small batches of 7-10 students, TIT ensures personalized attention. You’ll work on real-world simulations, learning to handle complex load cases and ensure code compliance, preparing you for actual industry challenges.

Why TIT Stands Out

Expert Faculty and Certification

Since 2011, TIT has been ISO 9001:2015 certified, delivering quality training. Our PV Elite Course in Mumbai is led by industry pros with extensive experience in pressure vessel design. You’ll earn Autodesk-authorized certificates, globally recognized by employers like Tata Consulting Engineers.

Affordable with Proven Placements

TIT keeps fees low to make training accessible. Our placement cell boasts an 80% success rate, with alumni like Shubham Patil (Tata Consulting Engineers, ₹6 lakhs/year) and Mahesh Gosavi (Tata Consulting Engineers, ₹7.2 lakhs/year). We offer resume-building, mock interviews, and connections to top firms.

Career Prospects After the PV Elite Course

Completing a PV Elite Course in Mumbai opens roles like pressure vessel designer, stress analyst, or equipment engineer. Starting salaries range from ₹4-6 lakhs annually, with experienced pros earning ₹10 lakhs or more. Mumbai’s oil and gas sector, with projects like refinery expansions, ensures high demand for PV Elite skills.